In production environments, maintaining a safe and clean atmosphere is always a priority. This is especially crucial in industries such as food production, pharmaceuticals, clean rooms, and animal husbandry. Airborne particles can contain bacteria, viruses, and fungal spores, which can spread throughout the space via the ventilation system. To protect both products and employees, ultraviolet (UV) air disinfection is becoming an increasingly popular solution.

Why Disinfect Air in Manufacturing?

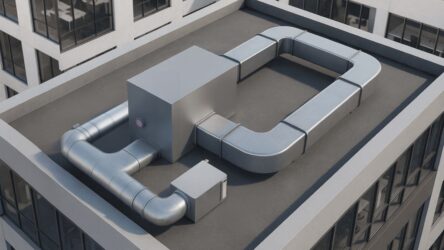

Many industries are governed by strict sanitary regulations, which directly mandate regular air disinfection. These regulations are based on the fact that, during operation, supply and exhaust ventilation systems in production areas, as well as the rooms themselves, accumulate dust, fungal spores, and microorganisms. These contaminants can quickly spread throughout the space via the air exchange system, posing a significant threat to sanitary safety. Therefore, it is essential to disinfect the air, and ultraviolet radiation stands out as one of the most effective methods.

Disinfection Methods: What to Choose

Several types of equipment are used to disinfect airflow:

- Recirculators: These create localized sterile zones but are less effective in large halls. High-powered units (over 1000 m³/h) are often economically unfeasible.

- Conveyor UV Irradiators: These work well for packaging lines but only disinfect specific areas, leaving the majority of the space untreated.

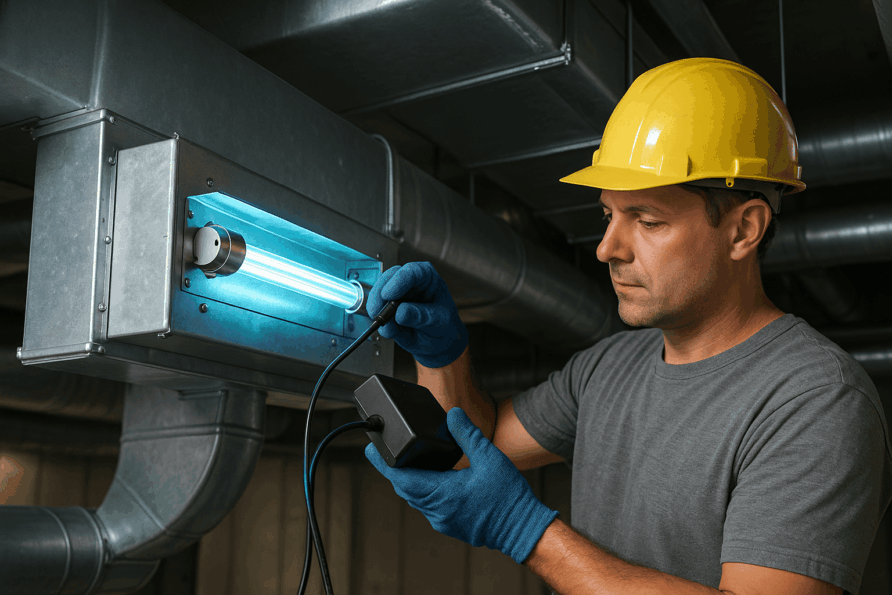

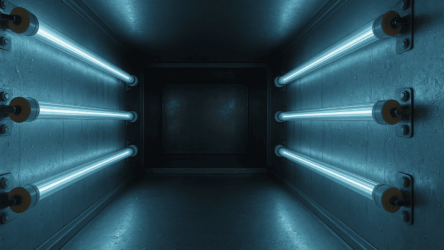

For systematic protection, the most rational solution is the installation of bactericidal sections in the ventilation ducts. These systems guarantee continuous disinfection of all incoming air. Integrating UV kit for self-installation into the ventilation system prevents mold and microorganism growth in production areas, while maintaining ease of use and high efficiency.

Implemented Projects

Our experience shows that such solutions are universally applicable across various sectors:

Food Production: UVL developed bactericidal sections for the ventilation system in a sauce production facility, ensuring air disinfection without interrupting the technological process.

Agricultural Industry: UV equipment for air disinfection was installed at an agro-industrial complex, preventing the spread of infections among animals.

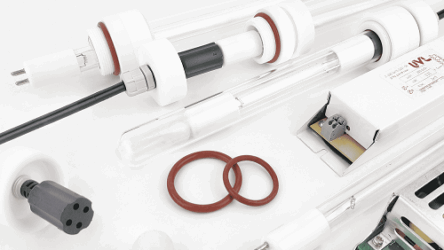

Clean Rooms and Pharmaceuticals: UVL supplied bactericidal UV kits, including UV lamps for ventilation, EPRA, mounting hardware, and connectors. This allowed customers to implement the technology without changing the entire ventilation system.

Conclusion

Air disinfection in manufacturing facilities using bactericidal lamps is one of the most effective methods for protecting both products and personnel. Unlike recirculators and conveyor irradiators, using ultraviolet sections in ventilation systems ensures that the entire incoming air is treated.

For industries in food production, pharmaceuticals, and agriculture, this solution helps maintain stable sanitary conditions, reduce risks, and meet ventilation system requirements for manufacturing facilities.