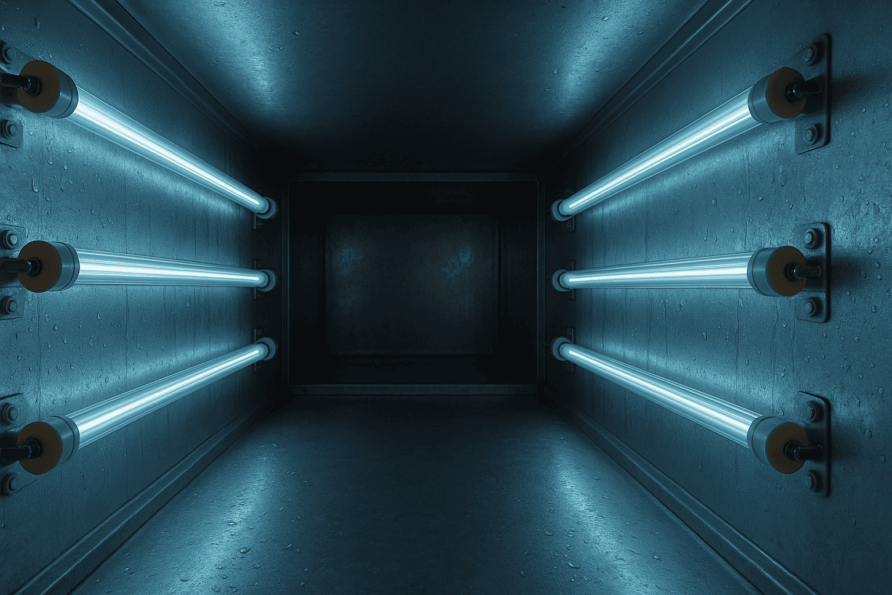

In standard supply ventilation systems, areas with excess moisture may appear due to humidification sections, condensation from temperature fluctuations, or the accumulation of debris in ducts. These conditions create a favorable environment for microorganism growth and become a health risk. The most effective solution is UV lamps, which, when used correctly, reliably disinfect the air even in high humidity conditions, while also protecting the equipment from pathogenic loads.

The Main Challenge: Moisture in Ventilation

Today, increasing attention is being given to airspace disinfection. UV radiation (with a wavelength of ~254 nm) disrupts the DNA and RNA structure of microorganisms, preventing their reproduction. According to health guidelines, UV-C light is an important method for maintaining hygiene.

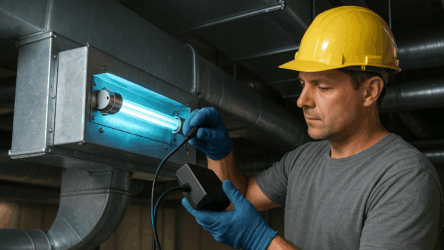

For larger spaces, recirculators can be used, but they often prove ineffective and economically unfeasible when the airflow exceeds 1000 m³/h. A much more reliable solution is to integrate bactericidal UV sections directly into the ventilation duct, where the airflow is treated directly.

However, there is a challenge: when relative humidity exceeds 75%, the efficiency of UV light significantly decreases. The reason is condensation, which obstructs the radiation and accelerates wear on electrical contacts. So, how can this be addressed?

Sealed Design: Key to Stable Operation

Using UV lamps with no exposed contact groups:

- Prevents condensation from affecting the equipment;

- Maintains radiation intensity despite temperature fluctuations;

- Increases lifespan and enhances reliability.

These solutions make disinfection sections more resistant to challenging operating conditions, meaning fewer breakdowns and consistent disinfection results.

Studies confirm that at high humidity and with proper usage, ultraviolet light reduces biofilm buildup on heat exchangers and maintains the sanitary state of ventilation ducts, thereby reducing the risk of secondary air contamination.

Two Simple Solutions for Implementing UV Disinfection

To give your ventilation system the disinfection power of ultraviolet light, we offer two options:

To give your ventilation system the disinfection power of ultraviolet light, we offer two options:

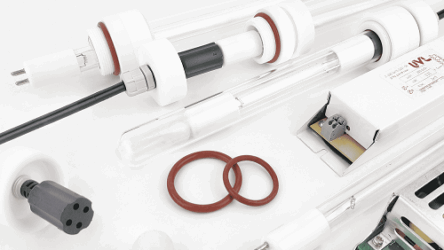

UV Kit for Self-Installation

The kit includes:

- UV radiation source;

- Electronic ballast (EPRA);

- Mounting clips;

- Ceramic connectors with wires.

With this kit, installation companies can easily integrate UV lamps into the duct system, transforming an ordinary supply ventilation system into one with disinfection capabilities. We provide a detailed manual that walks through the installation process step by step, with examples. It's possible to assemble your own bactericidal section with minimal costs.

UV sections for ventilation

For those who need a pre-assembled solution, we offer complete ventilation sections with built-in UV lamps. This option allows for immediate deployment of a working module.

In both cases, the result is the same—ventilation is upgraded to include air purification and disinfection.

Conclusion

Ventilation systems with humidification or temperature fluctuations often experience areas with excessive moisture, promoting the spread of pathogens. Using sealed UV lamps ensures the disinfection process remains effective and reliable. For installation companies, this is a versatile tool for upgrading systems, and for end-users, it guarantees a clean and safe microclimate.