Project Overview

This project involved a private medical clinic with an operating block classified as Category “A.” According to its technical standards, the air had to circulate through recirculation columns and then pass into a laminar flow zone that maintains a sterile field above the surgical area.

Laminar ventilation systems provide a directed stream of bacteria-free air, which is essential for preventing hospital-acquired infections and ensuring surgical safety.

Requirements and Challenges

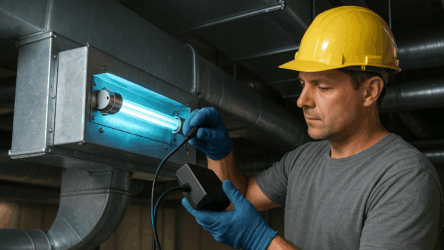

The task was to integrate UV air disinfection into the existing supply and exhaust system without redesigning the ductwork. Key requirements included:

- Treating airflow volumes up to 5,000 m³/h per column.

- Adapting to rectangular duct sections of 830 × 600 mm.

- Using a straight duct segment approximately one meter long.

- Operating reliably in warm indoor conditions.

- Offering both a ready-made UV section and a self-installation kit.

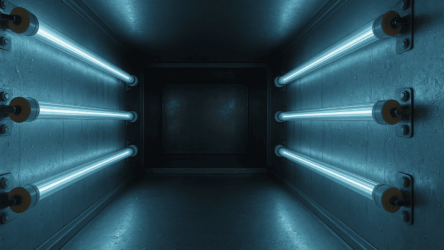

The clinic emphasized component reliability. UV lamps from previous projects had already proven their efficiency in demanding medical environments. The lamps had to emit ultraviolet radiation at 254 nm, effectively destroying pathogens, including spore-forming microorganisms, by breaking their DNA and RNA.

Proposed Solution

Two options were presented:

- UVL Aero 6 UV section – a built-in module rated for 5,000 m³/h, designed for ducts with a cross-section of 400 × 700 mm.

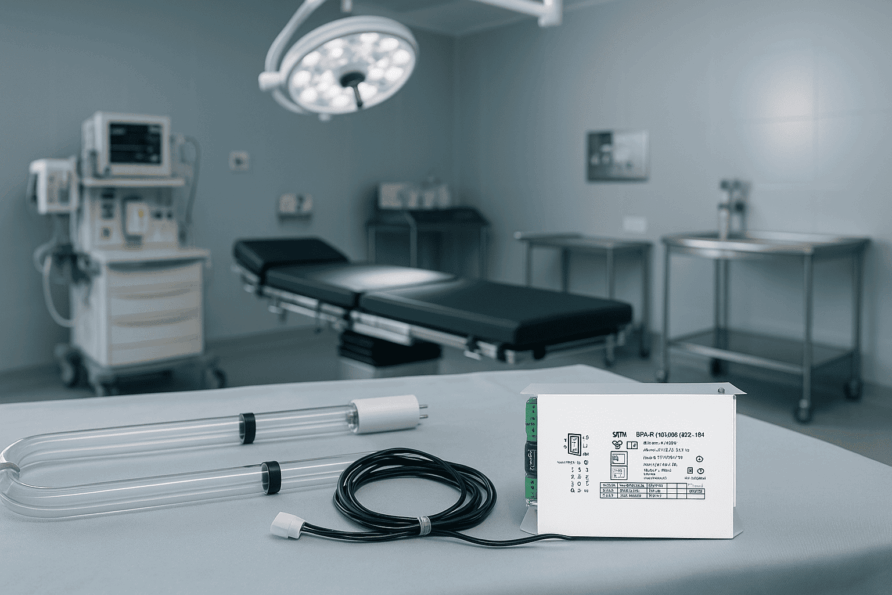

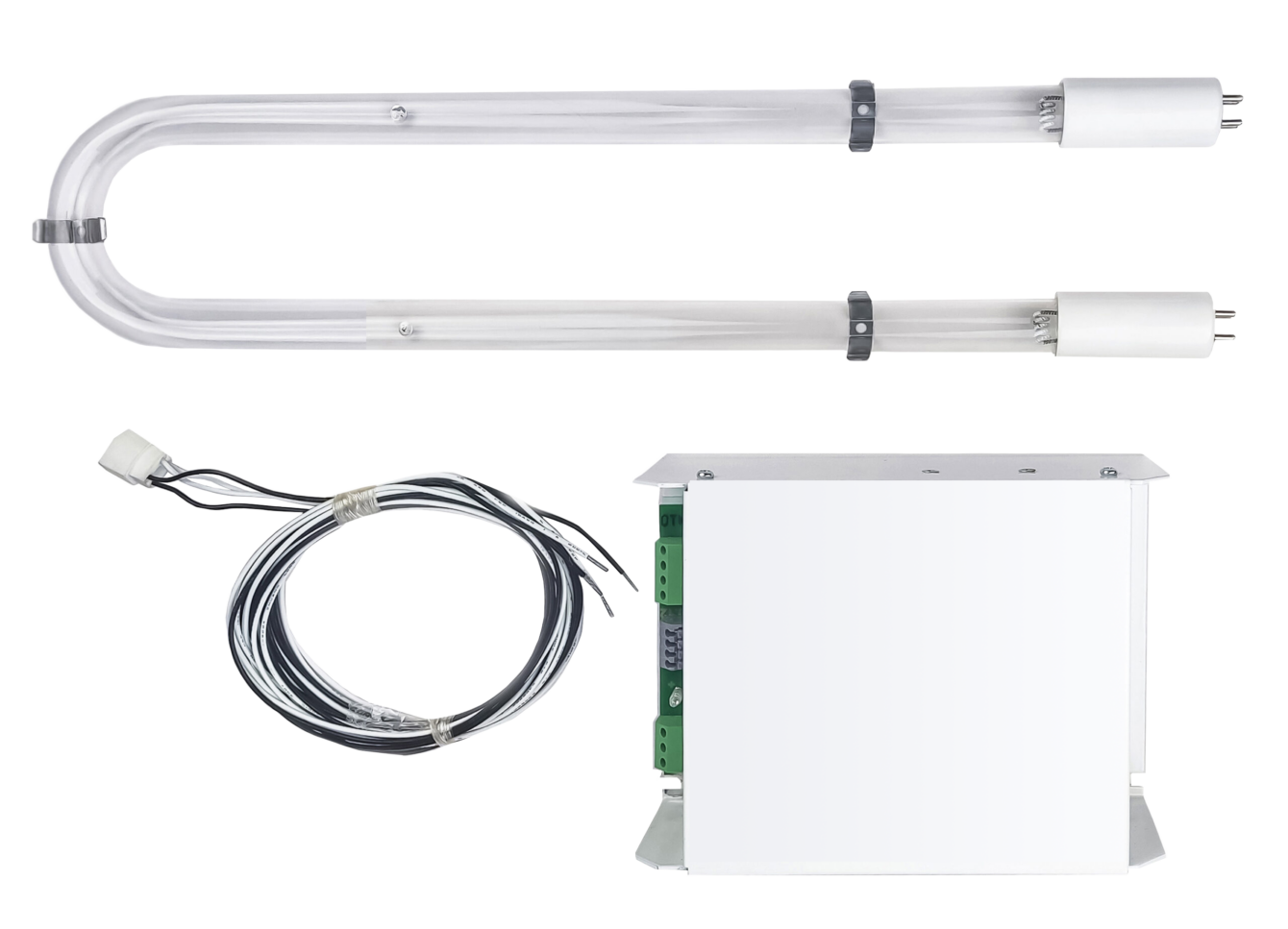

- A bactericidal UV kit for ventilation systems, including amalgam lamps, electronic ballasts, holders, and connectors.

After consultation with the clinic’s technical department, the second option was chosen, allowing UV components to be installed directly into the recirculation columns without modifying their structure.

Equipment Delivered

- 54 amalgam UV lamps UVL 19310-144 FLOW (service life: 16,000 hours).

- 54 electronic ballasts L-220-1x320 tailored to the lamps’ characteristics.

- 162 T5 metal clips for secure and stable mounting.

- 108 ceramic 4-pin connectors with 2000 mm wires for reliable connections.

These germicidal lamps ensure up to 99% disinfection efficiency against Staphylococcus aureus in ventilation systems. Such solutions are ideal for surgical blocks and sterile areas with strict hygiene requirements. All products were UVL-manufactured, fully compatible, and securely packaged to prevent damage. Any lamp damaged during delivery or failing within one year would be replaced quickly upon photo confirmation.

Implementation

The commercial offer and calculations were provided the same day as the client’s inquiry. Both approaches—ready-made UV section and installation kit—were presented. Thanks to clear communication, the specification was approved quickly, the contract signed, and delivery executed on schedule.

This project demonstrates that even complex ventilation configurations can be upgraded with UV disinfection technology to achieve stable, sanitary airflow while meeting all technical and hygiene standards.

Result

For healthcare facilities, laboratories, and operating rooms seeking reliable ultraviolet air disinfection, such integrated solutions provide sterilization without expensive ductwork changes.