Project Background

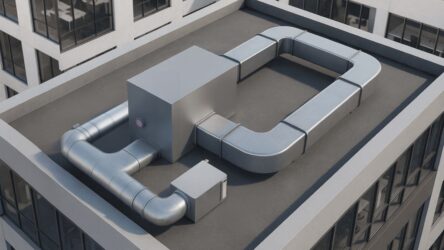

A food production site specializing in sauce packaging required UV air disinfection to protect product quality. Air is actively used in their technological process, including moving bottles of finished product. Contaminated air could pose a secondary contamination risk. The client needed a solution that maintained their current ventilation layout without modifying ducts.

Additionally, they requested three compact bactericidal UV sections measuring 200×200×1300 mm for other areas of the plant, each handling 1,200–1,300 m³/h airflow.

Proposed Solution

After reviewing the request, we proposed a two-part delivery:

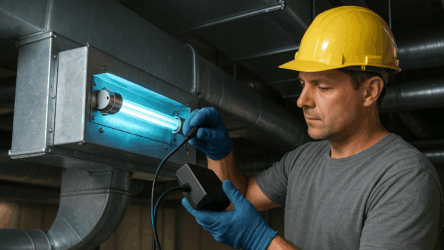

- Three UVL-Aero 2 UV sections for existing ducts (200×200 mm cross-section, up to 1,300 m³/h). These were custom-sized based on client drawings, ensuring seamless integration.

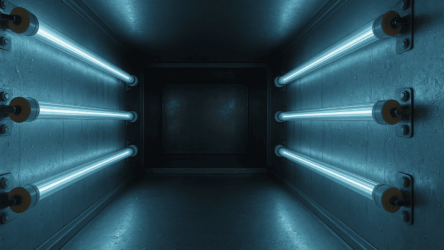

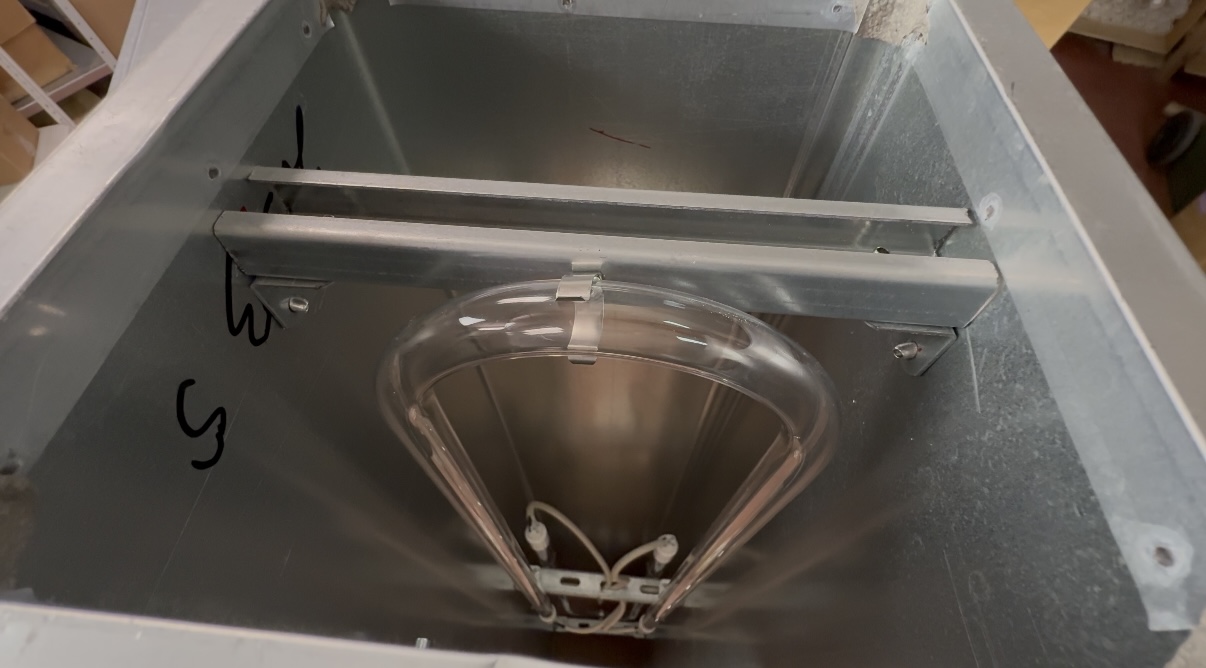

- One UVL-Aero 12 UV section, a high-capacity unit for disinfecting airflows up to 13,000 m³/h, fitted with 12 amalgam UV lamps and designed for installation in the main ventilation channel.

We also supplied:

- Six spare UV lamps UVL 19310-144 FLOW.

- A single-channel control cabinet for one electronic ballast (EPRA) and a 12-channel cabinet for multiple EPRAs.

- Electronic ballasts L-220-1x320-2212-150.

- Documentation verifying the equipment’s safety for food production environments.

Equipment Specifications

UVL-Aero 12

- 12 high-power amalgam UV lamps.

- Capacity: 33,200 m³/h at 90% efficiency; 25,800 m³/h at 95%.

- Stainless-steel housing.

- Designed for integration into central ventilation channels.

UVL-Aero 2 (×3)

- 2 UV lamps per section.

- Capacity: up to 1,300 m³/h.

- Dimensions: 200×200×1300 mm (customizable).

- Ideal for local airflow disinfection.

Implementation

We maintained prompt communication with the client, including several calls with the chief mechanic, drawing approvals, and clarifying connection points and service hatch placement. Full technical descriptions confirmed compliance with food industry standards.

Despite a split payment structure (50% upfront, 50% on delivery), the equipment was quickly moved into production. Installation and commissioning are now complete, and the system is fully operational. The client reported high satisfaction with the result.

Benefits for Food Production Facilities

- Protects packaged products from airborne contamination.

- Adapts to existing ventilation without costly modifications.

- Offers both high-capacity and localized air disinfection solutions.

Includes spare parts and control systems for reliable long-term use.