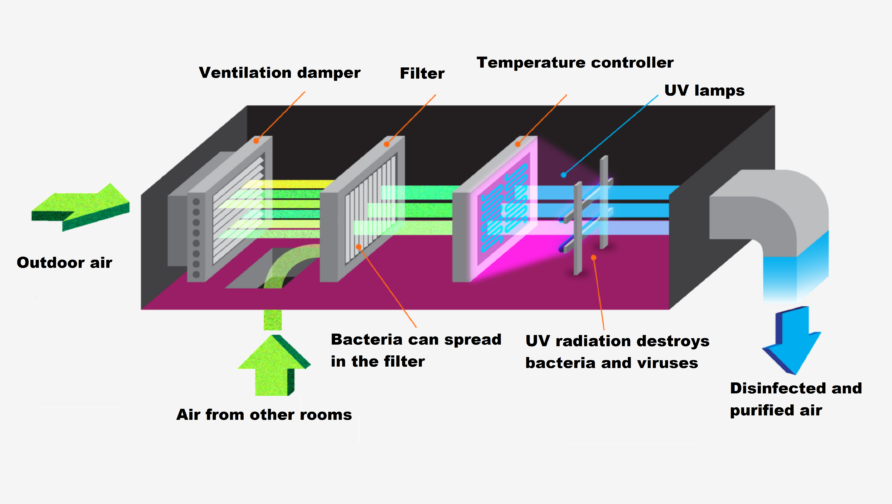

Maintaining clean and pathogen-free air is essential for ensuring healthy indoor environments, particularly in commercial, medical, and industrial settings. Over time, dust, moisture, and organic particles accumulate within ventilation systems, creating an ideal breeding ground for bacteria, viruses, and mold spores. While traditional air filters help remove larger contaminants, they cannot fully eliminate airborne microorganisms. To address this issue, germicidal UV sections are integrated into ventilation systems, utilizing ultraviolet radiation (254 nm) to neutralize harmful pathogens and enhance overall air quality.

How germicidal UV sections improve air disinfection

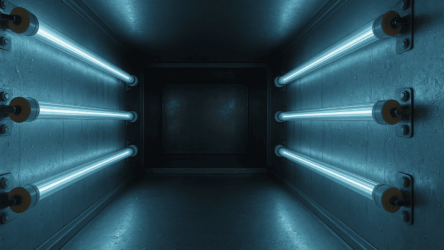

UV disinfection systems are strategically installed within ventilation ducts to ensure continuous air purification. As air passes through the UV irradiation zone, it is exposed to 254 nm UV-C light, which breaks down the DNA and RNA of microorganisms, preventing them from reproducing. This method significantly reduces the risk of airborne disease transmission, making it a critical component of modern air sanitation solutions.

Key components of a UV disinfection section

A well-designed UV ventilation system includes several essential elements:

- Durable housing – Constructed from stainless steel or galvanized metal, ensuring resistance to UV radiation and humidity for long-term operation.

- High-efficiency UV lamps – Uses low-pressure amalgam lamps, which are more powerful and long-lasting than standard mercury lamps.

- Power control unit – Equipped with electronic ballasts, a cooling system, and an operating hour meter, allowing for easy performance monitoring.

- UV-resistant wiring and connectors – Designed for secure integration into ventilation ducts of various sizes.

- Maintenance access panel – Enables quick and convenient lamp replacement, simplifying system upkeep.

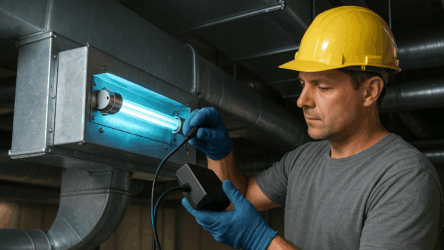

Installation and maintenance best practices

To maximize efficiency and safety, proper installation and routine maintenance of UV sections are crucial.

- Ensure accessibility for maintenance – The UV section should be placed where lamp replacement and servicing can be performed with ease. If space is limited, a dedicated maintenance area should be considered.

- Position the control cabinet within reach – The electronic ballast control unit should be installed within 10 meters of the UV section for simplified operation and monitoring.

- Maintain airtight sealing – The UV section must be fully enclosed to prevent UV light leakage, ensuring safety for personnel and system efficiency.

- Operate within recommended temperature range – UV lamps function best between +10°C and +35°C. Failure to maintain this range may lead to reduced effectiveness and shorter lamp lifespan.

Routine maintenance requirements:

- Regular lamp inspections – Monitor UV lamps for intensity loss and contamination buildup.

- Quartz sleeve cleaning – Periodic cleaning prevents dust accumulation, ensuring maximum UV transmission.

- Lamp replacement – UV lamps typically last 9,000 to 16,000 hours and should be replaced as soon as their output declines.

Choosing the right UV disinfection section for ventilation

Selecting an appropriate UV ventilation section depends on several factors:

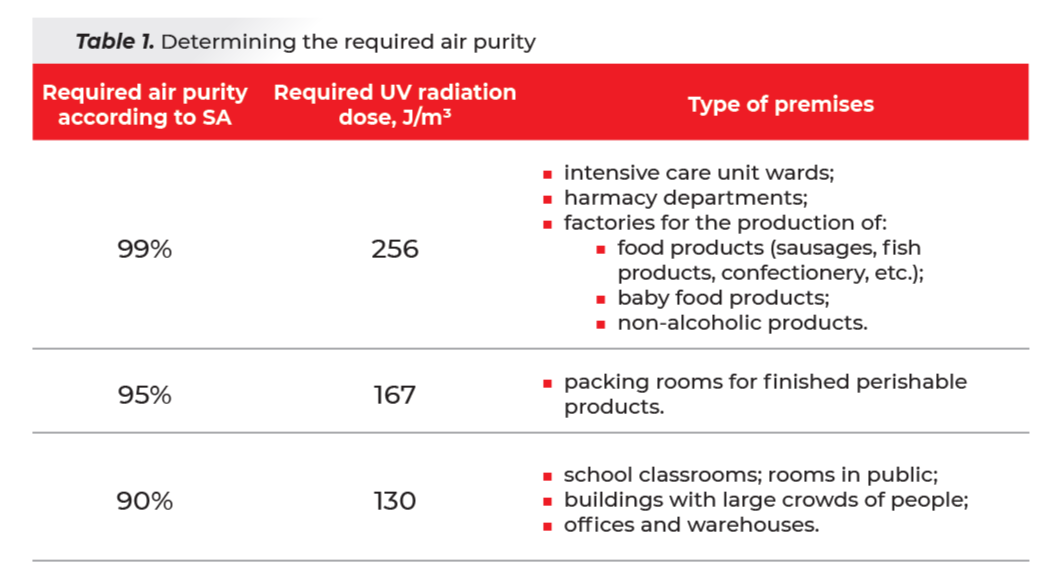

- Required air purity level – Air disinfection standards vary across industries; healthcare and cleanroom environments demand the highest levels of purification.

- Ventilation duct dimensions – The size and shape of the duct influence the UV system's configuration and placement.

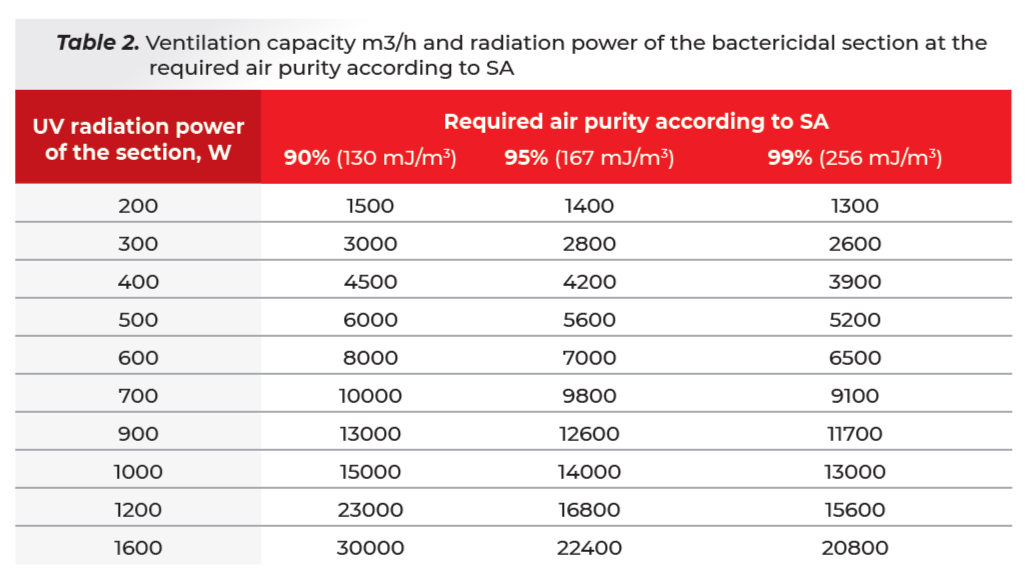

- Airflow volume and ventilation rate – The system's air capacity (m³/h) determines the necessary UV lamp power for effective disinfection.

Example: implementing a UV disinfection system in an office space

Consider an office environment with a ventilation capacity of 1680 m³/h. To achieve optimal air disinfection, the UV section is installed after the heat exchanger, ensuring all incoming air is treated before distribution.

- The ventilation duct measures 300×400 mm, dictating the UV system's physical dimensions.

- To meet office air purity regulations (minimum 90%), a UV dose of 130 J/m³ is required.

- Based on system performance tables, the nearest higher capacity is 3000 m³/h, which necessitates a 300 W UV section.

Using this data, a UVL-Aero germicidal UV section is selected, offering precise power output and proper system integration.

Why UV disinfection sections are a vital investment

UV ventilation systems provide advanced air purification and offer key benefits, including:

- Elimination of airborne pathogens – Effectively destroys bacteria, viruses, and mold spores, reducing infection risks.

- Chemical-free air sanitation – Operates without ozone or harmful chemicals, making it a safe, eco-friendly solution.

- Long lifespan and low maintenance – Amalgam UV lamps deliver higher efficiency and durability than conventional options.

- Compliance with air quality standards – Ideal for hospitals, offices, manufacturing facilities, and public buildings.

Conclusion

Integrating germicidal UV sections into ventilation systems is a proven and efficient method for enhancing indoor air quality. Proper selection, installation, and maintenance ensure optimal disinfection performance and long-term reliability.

For customized UV ventilation solutions, UVL offers a diverse range of high-quality air disinfection products. Our experts are available to provide professional system selection and installation guidance, ensuring that you achieve maximum air purification efficiency.