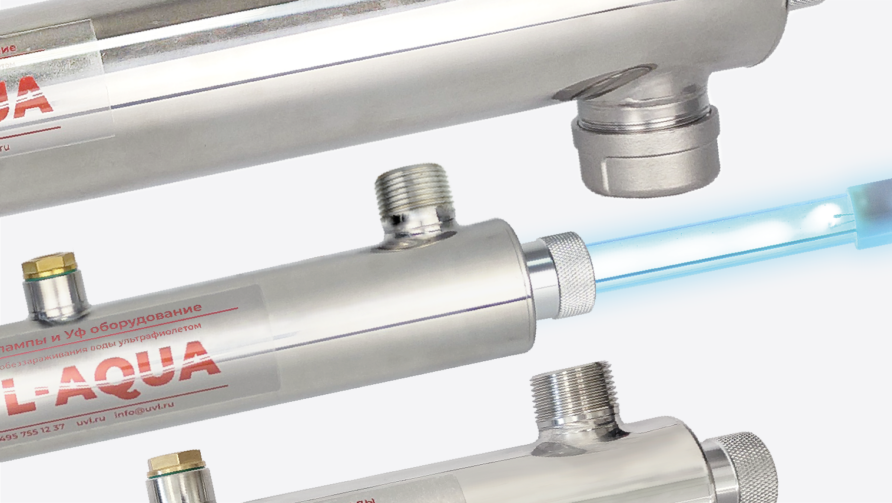

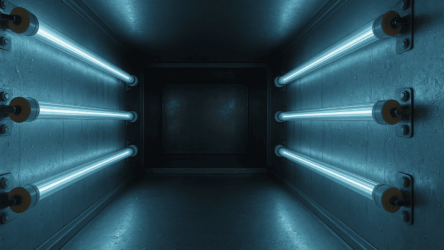

Ensuring strict hygiene and water safety in food production is essential for compliance with sanitary standards and product quality assurance. UV disinfection systems play a crucial role in eliminating microorganisms from process water, providing chemical-free sanitation. For maximum durability and resistance to harsh conditions, UV installations made from AISI 316 stainless steel are the ideal choice, offering superior corrosion resistance, longevity, and ease of maintenance.

Why AISI 316 stainless steel is the best choice for UV systems

AISI 316 stainless steel is engineered for use in demanding industrial environments, where exposure to moisture, acids, and salts can cause rapid material degradation. This alloy contains molybdenum, which enhances its resistance to corrosion and extends the lifespan of equipment used in food production.

Key composition of AISI 316 stainless steel

- Chromium: 16–18%

- Nickel: 10–14%

- Molybdenum: 2–3%

This composition makes AISI 316 highly resistant to oxidation, chemical exposure, and mechanical stress, making it the preferred material for UV disinfection systems in food processing.

Advantages of AISI 316 UV systems in food production

1. Superior corrosion resistance

Water used in food processing often contains salts, acids, and other aggressive compounds, which can cause material degradation. AISI 316 stainless steel outperforms standard AISI 304 in corrosion resistance:

- AISI 316 corrosion rate: <0.02 mm/year

- AISI 304 corrosion rate: ~0.05 mm/year

This means that UV systems made of AISI 316 last significantly longer, reducing maintenance costs and ensuring consistent water disinfection.

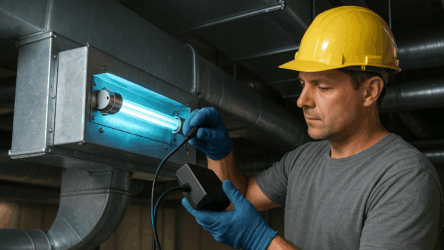

2. High hygiene standards and easy maintenance

The non-porous, smooth surface of AISI 316 stainless steel prevents bacterial growth and contamination buildup, ensuring easier cleaning and sanitization.

- Risk of contamination on AISI 316 surfaces is 20–30% lower than on standard materials.

- Smooth structure minimizes biofilm formation, reducing the risk of cross-contamination in food production.

3. Resistance to extreme temperatures

Food industry processes often involve high-temperature sterilization and rapid cooling cycles. AISI 316 stainless steel maintains mechanical strength and structural integrity under extreme conditions, ensuring consistent performance across various applications.

4. Cost-effective and long-lasting operation

Using corrosion-resistant materials significantly reduces maintenance costs and equipment downtime. UV installations made of AISI 316 stainless steel last 30% longer than those made from lower-grade alloys.

Expected service life:

- AISI 316 UV systems: 15–20 years

- AISI 304 UV systems: 10–12 years

Applications of AISI 316 UV disinfection systems in the food industry

UV systems made from AISI 316 stainless steel are widely used in food and beverage production, where water quality and hygiene are critical:

- Beverage manufacturing (bottled water, juices, beer)

- Dairy processing (milk, cheese, yogurt production)

- Canning industry (fruit, vegetable, and seafood preservation)

- Process water treatment (removal of microbial contaminants)

- Sanitization of equipment and raw materials

Conclusion

AISI 316 stainless steel UV disinfection systems are the most reliable and cost-effective solution for ensuring high sanitation standards in the food industry. Their exceptional corrosion resistance, durability, and ease of maintenance make them ideal for food production facilities seeking long-term efficiency and reduced operational costs.

By integrating UV water treatment solutions made from AISI 316 stainless steel, food manufacturers can achieve superior hygiene, extended equipment lifespan, and full regulatory compliance, ensuring safe and high-quality products for consumers.