Project Background

A leading pharmaceutical company needed to maintain microbiological purity in its polypropylene water tanks after reverse osmosis treatment. The tanks, horizontal in design and holding up to 2 m³, had variable water levels as inflow and outflow occurred by gravity or pumps.

Challenges

- Prevent microbial growth in stored water without using chemical reagents.

- Ensure reliable operation despite fluctuating water levels.

- Avoid modifications to existing tanks or disruption to production processes.

Proposed Solution

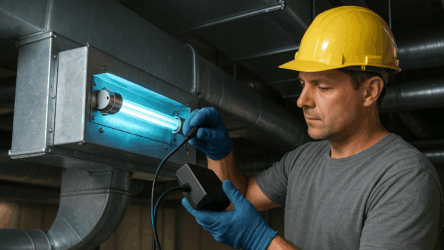

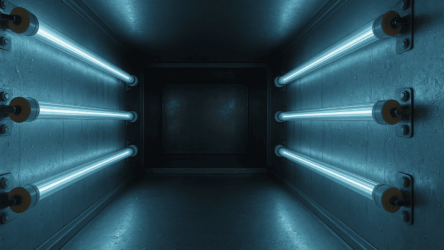

Our engineers analyzed the site’s technical documentation and recommended the UVL-Mod 19130 submersible UV module. The client tested the system in a spare tank and confirmed its high efficiency within weeks. The module was installed in continuous operation, requiring no special maintenance while meeting all water disinfection standards.

Technical Specifications

- Lamp power: 130 W.

- UV output: 45 W.

- Module length: 914 mm.

- Lamp type: amalgam, ozone-free UV lamp.

- Lamp life: 16,000 hours.

- Water temperature range: 5–40 °C.

- Maximum flow rate: 5 m³/h.

- Recommended pipe diameter: 90–100 mm.

Package Contents: Fluoroplastic sealing unit, quartz sleeve for protection, 10 m power cable, and a hermetic box.

Advantages of UVL-Mod 19130

- Contact-free disinfection with no chlorine or reagents.

- No by-products or residual substances.

- Energy-efficient performance with minimal maintenance.

- Reliable operation even with unstable water levels.

Results

The pharmaceutical plant confirmed the UV module’s effectiveness in eliminating bacteria and ensuring safe water quality. The system operated smoothly without adjustments or extra service, making it an ideal fit for their needs. Due to its success, the company plans to expand its use across other production sites.

Do you want to introduce UV disinfection?

Contact us — we will select the optimal UV module, make calculations and arrange delivery as soon as possible.