Project Background

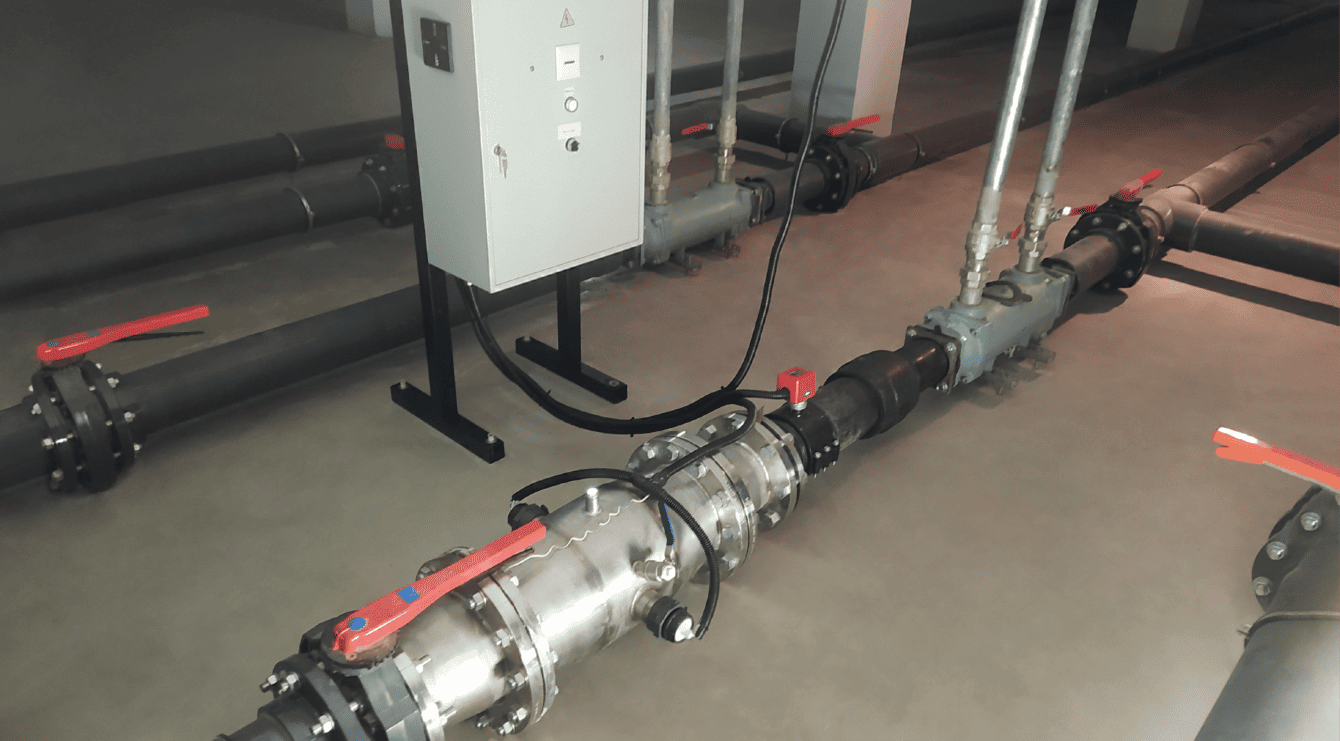

A large sports swimming pool began upgrading its engineering systems by installing UVL Aqua Medium 150, a modern UV water disinfection unit. The pool hosts daily athlete training, children’s classes, and competitions, making reliable and efficient ultraviolet water treatment essential.

Why UVL Aqua Medium 150

The selection considered water treatment specifics, load on the system, and strict hygiene standards. UVL Aqua Medium 150 met all requirements:

- Capacity: up to 150 m³/h.

- Medium-pressure UV lamp power: 2400 W.

- UV dose: 60 mJ/cm², enough to inactivate pathogenic microorganisms.

- Working pressure: up to 6 bar, compatible with most water supply and circulation systems.

- Housing: corrosion-resistant stainless steel AISI-316 with a quartz sleeve-protected UV lamp for stable operation.

- Pipe connection diameter: 160 mm, ensuring easy integration into the existing network.

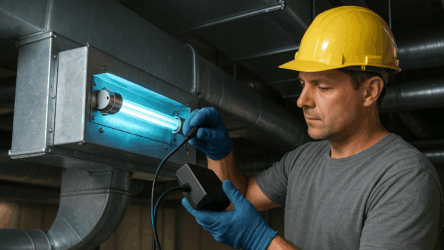

Installation Process

Following contract signing and delivery, the installation team began work in close cooperation with the facility’s technical staff. Tasks included pipeline integration, connection to the control panel, and configuration of flow sensors and automatic UV shutoff in case of circulation loss.

Special attention was given to:

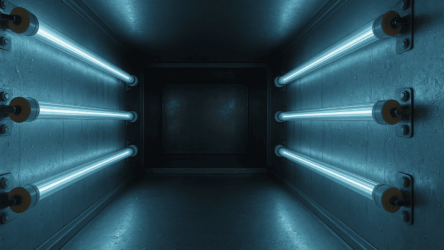

- Proper UV lamp placement.

- Sealing, pressure resistance, and electrical safety.

- Cavitation protection and ensuring uniform bactericidal UV flow within the reactor.

Commissioning and Testing

The commissioning phase involved:

- Leak testing of all joints.

- Measuring UV dose at the outlet.

- Calibrating protection systems and automation.

- Training personnel on equipment use.

All procedures were documented, and the client received a full set of records, diagrams, certificates, and technical passports.

Benefits for the Facility

Once operational, the pool will benefit from:

- Reliable, eco-friendly UV water disinfection without chemicals.

- Consistent microbiological indicators meeting health standards.

- Reduced consumption of coagulants, chlorine, and other reagents.

- Continuous, safe operation of UV disinfection sections throughout the season