Effective ballast water treatment is a critical environmental and regulatory requirement in the global shipping industry. To prevent the spread of invasive species and harmful microorganisms, ships must comply with the International Ballast Water Management Convention (BWM Convention), which mandates proper water disinfection before discharge. Ultraviolet treatment has emerged as one of the most efficient, eco-friendly, and chemical-free solutions, particularly when utilizing UV systems made from AISI 316 stainless steel. This material offers superior durability, corrosion resistance, and long-term operational reliability, making it ideal for harsh marine conditions.

Why AISI 316 stainless steel is ideal for UV systems in shipping

AISI 316 stainless steel is specifically designed to withstand the extreme conditions of marine environments, where ballast water contains high levels of salt, chemical pollutants, and organic matter. This high-grade alloy includes molybdenum, which significantly enhances its resistance to corrosion and chemical degradation, ensuring long-term reliability.

Key composition of AISI 316 stainless steel

- Chromium: 16-18%

- Nickel: 10-14%

- Molybdenum: 2-3%

This unique composition provides high resistance to saltwater exposure, aggressive chemicals, and biofouling, making it the preferred choice for marine-grade UV disinfection units.

Advantages of AISI 316 UV systems for ballast water treatment

1. Unmatched corrosion resistance

In harsh marine environments, continuous exposure to saltwater, hydrocarbons, and industrial pollutants accelerates equipment wear. AISI 316 stainless steel significantly outperforms standard alternatives in corrosion resistance:

- AISI 316 stainless steel corrosion rate in seawater: <0.02 mm/year

- AISI 304 stainless steel corrosion rate: ~0.05 mm/year

This means that UV disinfection units made from AISI 316 last up to 2.5 times longer than those made from less corrosion-resistant alloys.

2. High durability in chemically aggressive environments

Ballast water can contain traces of oil, chemical residues, and biological contaminants, which can rapidly degrade inferior materials. The molybdenum content in AISI 316 stainless steel provides exceptional resistance to chlorides and acidic conditions, preventing structural damage:

- Corrosion rate in a 5% sodium chloride solution:

- AISI 316 stainless steel: <0.01 mm/year

- AISI 304 stainless steel: ~0.03 mm/year

This superior resistance means AISI 316 is three times more resistant to chloride-induced corrosion compared to AISI 304, ensuring longer-lasting performance in demanding maritime conditions.

3. Extended service life and cost savings

Investing in AISI 316 UV disinfection units reduces maintenance and replacement costs over time, making it a highly economical choice for shipowners and operators:

- AISI 316 UV systems lifespan: 15-20 years with proper maintenance

- AISI 304 UV systems lifespan: 10-12 years

This extended durability translates to lower operational costs, reduced downtime, and enhanced efficiency for shipping companies.

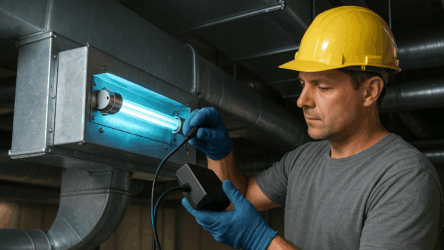

The benefits of UV ballast water disinfection

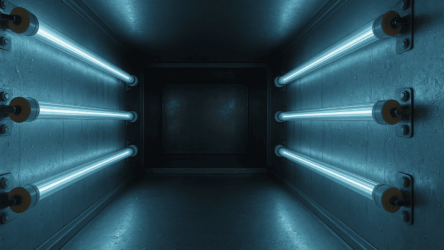

Unlike traditional chemical treatments, UV disinfection is a safe, eco-friendly, and regulatory-compliant solution for ballast water treatment. UV systems efficiently neutralize bacteria, viruses, and invasive species without altering the water's chemical properties or introducing harmful byproducts.

- Elimination of pathogens: Up to 99.9% of microorganisms destroyed

- High flow capacity: Treats up to 1000 m³/hour of ballast water

- No chemical additives: Ensures compliance with environmental regulations

Material comparison

| Characteristics | AISI 316 | AISI 304 | Carbon steel |

| Corrosion resistance | Very high | High | Low |

| Chloride resistance | Excellent | Satisfactory | Poor |

| Service life in seawater | 15-20 years | 10-12 years | 5-7 years |

| Resistance to chemical influences | High | Medium | Low |

Conclusion

For shipping operators seeking a long-term, high-performance ballast water treatment solution, AISI 316 stainless steel UV disinfection units offer unmatched reliability, superior corrosion resistance, and cost-efficiency. Engineered for marine-grade durability, these systems effectively comply with international environmental standards, safeguard ecosystems, and optimize operational efficiency.

By investing in advanced UV ballast water treatment technology, shipping companies can ensure sustainable and responsible maritime operations, while significantly reducing maintenance costs and regulatory risks.