Reliable disinfection of wastewater requires not only the right equipment, but also consistent maintenance and proper operation. Even the best-designed UV disinfection systems can lose effectiveness over time if not maintained. This guide outlines key practices to ensure optimal performance and extend the lifespan of your UV sterilizer.

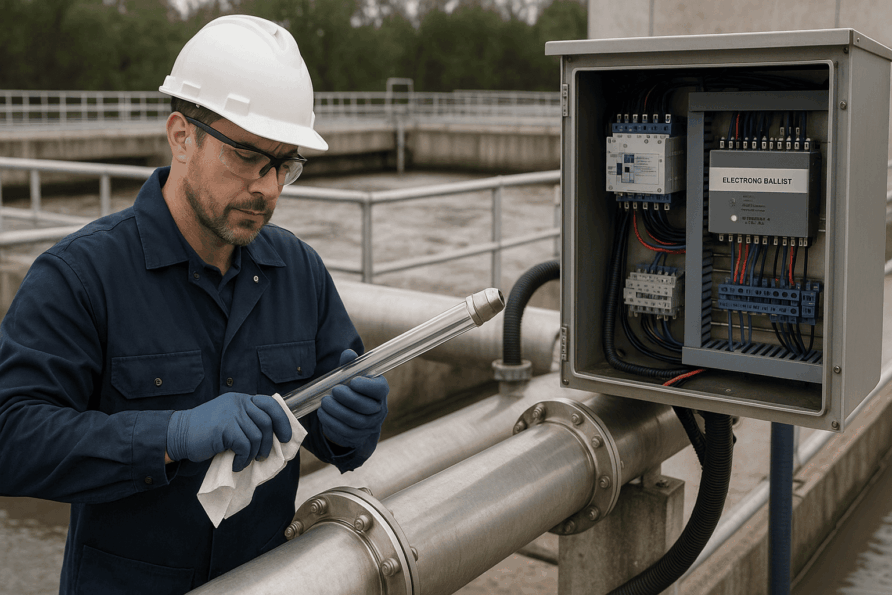

1. Clean the Quartz Sleeves Regularly

Each germicidal UV lamp is housed inside a quartz sleeve, which protects it from direct contact with water. Over time, this sleeve may accumulate deposits from suspended particles in the treated water, reducing UV transmission.

Solution: Clean the sleeves regularly using acidic descaling solutions to maintain UV efficiency and prevent performance drop-offs.

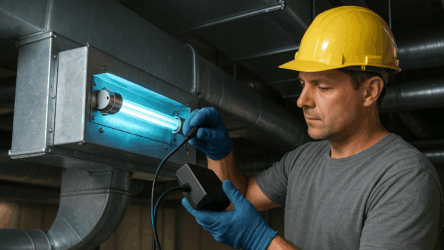

2. Replace UV Lamps on Schedule

Every UV lamp has a limited service life:

- Mercury UV lamps typically last ~11,000 hours

- Amalgam lamps can last up to 16,000 hours

As their output weakens over time, continuing to operate expired lamps may compromise disinfection levels. Many UVL sterilizers include built-in hour meters and status indicators to help track lamp performance.

3. Inspect Electrical and Control Components

The control cabinet and wiring are vital to system stability. Loose connections, worn relays, or software faults can cause downtime or reduce UV output.

Preventive checkups of electrical terminals, fuses, and the electronic ballast ensure consistent operation and help avoid unexpected failures.

4. Avoid Frequent On/Off Cycling

Switching UV lamps on and off too often reduces their life expectancy and can stress power supply components.

Best practice: Keep the disinfection system running continuously during flow operations, minimizing cycles to extend both lamp life and system stability.

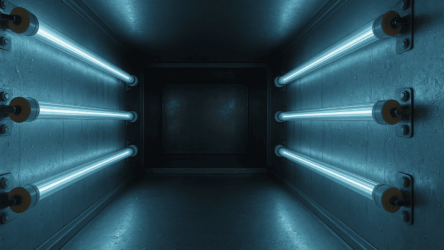

5. Ensure Proper Ballast Matching and Cabinet Ventilation

The UV ballast regulates current and ignition. It must be compatible with your lamp type, and adequately cooled — especially when housed in compact control panels.

Tip: Use cabinets with active ventilation (fans or passive airflow) to prevent heat buildup, which can degrade components and shorten system life.

6. Only Operate Under Flowing Water Conditions

Never start a UV water disinfection system without fluid in the chamber. Dry runs cause overheating and lamp damage.

A continuous water flow ensures even irradiation, protects internal components from thermal stress, and extends equipment lifespan.

Conclusion: Preventative Maintenance Saves Money

Regular maintenance of your UV lamp for wastewater systems leads to:

- Better disinfection performance

- Lower operating costs

- Fewer emergency repairs

- Longer equipment lifespan

UVL provides complete ultraviolet water disinfection systems tailored for wastewater facilities of any scale — from industrial plants to decentralized treatment stations. Our team offers consultation, spare parts, and full lifecycle suppor