Maintaining hygiene in food production is essential, especially during the packaging process. Effective decontamination of containers and contact surfaces prevents the spread of pathogenic microorganisms, preserves product quality, and enhances consumer safety. One of the most advanced methods for achieving this is ultraviolet disinfection at 254 nm, which is widely used in conveyor-based sanitation systems.

The risk of microbial contamination on conveyor lines

Conveyor systems in the food industry are continuously exposed to pathogenic microorganisms, including bacteria and viruses. These contaminants can:

- Settle on packaging containers and production surfaces, increasing the risk of foodborne illnesses.

- Accelerate product spoilage, leading to financial losses and waste.

- Compromise consumer safety, making rigorous disinfection essential.

UV technology for efficient disinfection

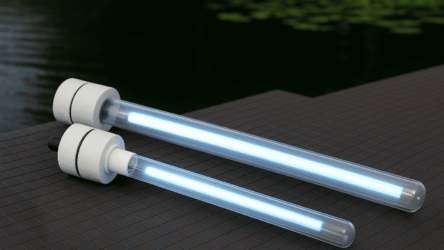

To address these concerns, specialized UV disinfection units have been developed for conveyor integration. These 254 nm UV irradiators are designed to eliminate microorganisms effectively, preventing their growth and spread. They can be:

- Standardized for universal use in food processing lines.

- Custom-built to suit specific industry requirements, ensuring optimal sanitation coverage.

Key factors influencing UV disinfection efficiency

The effectiveness of UV disinfection depends on several critical factors:

- UV dose – The intensity and duration of UV exposure determine how effectively pathogens are inactivated.

- Material properties of packaging – Some packaging materials absorb or reflect UV light, influencing disinfection efficiency.

- Contamination levels – Higher contamination levels may require pre-cleaning before UV exposure for optimal results.

Determining the required UV dosage

The UV dose is a key factor in effective disinfection and is measured in millijoules per square centimeter (mJ/cm²). It is calculated as the product of UV intensity and exposure time.

- Most bacteria require 10 to 100 mJ/cm² for effective decontamination.

- Viruses and spores may need up to 1000 mJ/cm² to ensure complete inactivation.

- Environmental factors, such as distance from the UV source, material transparency, and conveyor speed, impact the actual dose received by the container surface.

Optimizing UV disinfection for efficiency

To maximize disinfection effectiveness while minimizing energy consumption, manufacturers should:

- Regularly monitor UV intensity and dosage levels.

- Adjust conveyor speed to ensure proper exposure.

- Account for material properties to ensure consistent pathogen elimination.

Utilizing 254 nm UV disinfection for container sanitation is a highly effective and chemical-free method of ensuring cleanliness in food production. Proper system configuration and dose optimization significantly reduce the risk of microbial contamination, ensuring product safety, extended shelf life, and compliance with hygiene regulations. UV disinfection is now an essential part of modern food manufacturing, helping companies achieve the highest standards of sanitation and quality control.