Background: Tackling Biofilm in Recirculating Water

In early March, UVL was approached by a furniture manufacturing facility facing persistent biofilm issues in its ventilation humidification system. The site had a pre-installed ventilation setup featuring a cellulose evaporative filter and open water reservoir for air humidification. Despite using post-reverse-osmosis water, stagnant conditions and high indoor humidity led to recurring organic contamination, particularly clogging the circulation pump.

The client had attempted to resolve the issue using a household UV sterilizer designed for aquariums (rated for ~400 liters), but microbial buildup continued. The goal was to find an industrial-grade solution that could eliminate biofilm, protect equipment, and potentially extend to air disinfection in the supply path.

System Requirements & UVL’s Approach

The water reservoir (60×100 cm) collected water via drip flow through an evaporative medium. While the filtration source was sound, the lack of water renewal and constant warmth created an ideal environment for biofilm formation on both surfaces and submerged components.

In addition to eliminating bacteria in the water, the client wanted to:

- Prevent growth on the inner surfaces of the tank

- Reduce clogging in the pump

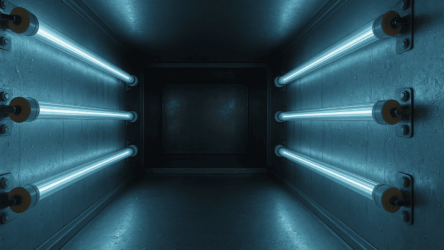

- Explore optional UV air disinfection near the intake zone

Solution: Immersion UV Modules for Localized Water Sterilization

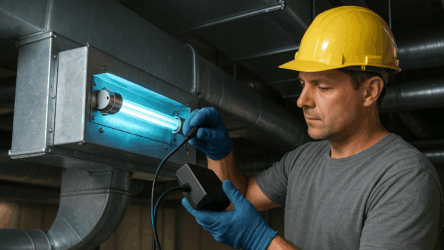

After an engineering assessment, UVL recommended installing four UVL-Mod 28 immersion modules, each rated at 28W. These modules deliver germicidal UV light in a concentrated radius (~25 cm), making them ideal for shallow tanks.

The modules were strategically positioned along the tank’s long axis to maximize exposure. Each included:

- High-efficiency UV lamps for water

- Quartz sleeves with sealed ends

- Hermetic stainless mounting assemblies

- Electronic ballasts (EPRA)

- Shielded 4P SE waterproof cabling

All components were tailored for compatibility with the client’s system, ensuring ease of integration with minimal structural changes.

Technical Highlights and Integration

One critical concern was UV impact on existing plastic parts — especially the float valve, which was prone to degradation under UV exposure. UVL recommended replacing it with a stainless steel float, which the client sourced independently.

Each immersion UV lamp was installed through a drilled port and secured with PTFE locknuts, offering a firm, leak-resistant hold even in low-turbulence conditions.

Benefits for the Client

The new UV disinfection system provided:

- Reliable microbial control in stagnant water

- Prevention of surface biofilm and algae

- Reduced maintenance for pumps and humidifier parts

- Fewer service interruptions and cleaning cycles

- Higher air hygiene due to cleaner humidification process

This custom solution fit seamlessly into the existing HVAC setup without major redesign. UVL continues to offer bespoke support for clients across industries needing sterilization for humidifiers, tanks, ducts, and other ventilation components.

Need a water disinfection solution for your ventilation or humidification system?

UVL designs tailored ultraviolet systems — based on your equipment, your needs, and your airflow parameters.