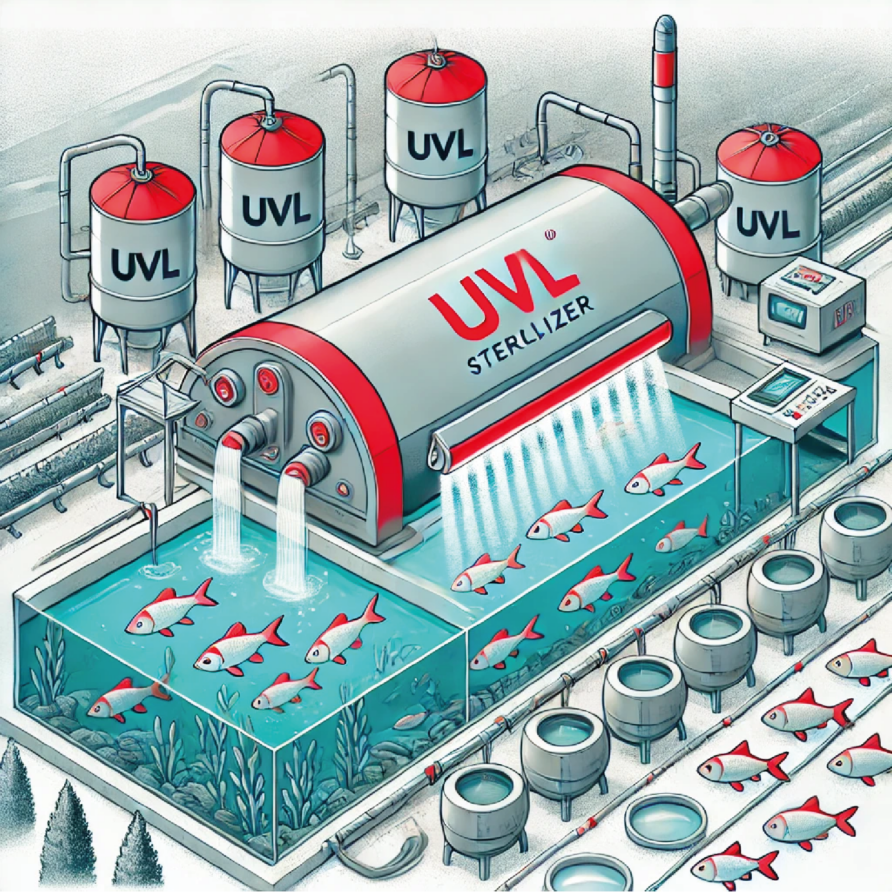

Ultraviolet technology has become an essential component in recirculating aquaculture systems (RAS), ensuring optimal water quality and disease prevention in fish farming. By utilizing UV disinfection, aquaculture facilities can effectively eliminate pathogens, creating a safer and more sustainable environment for fish growth. This method plays a vital role in maintaining water purity without altering its chemical composition, making it an eco-friendly solution for modern fish farms.

How UV water treatment works in aquaculture

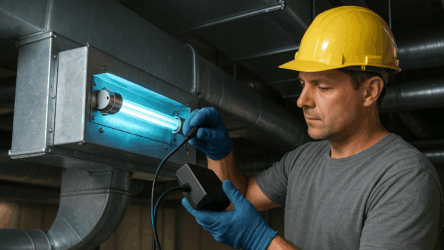

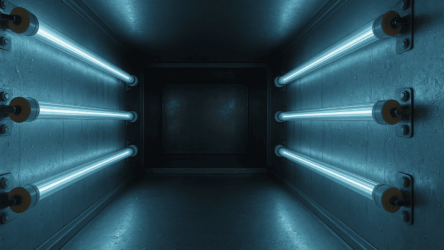

UV disinfection operates by passing water through a sterilization chamber equipped with UV lamps emitting 254 Nm wavelength light. This germicidal radiation destroys the DNA and RNA of bacteria, viruses, and parasites, preventing their reproduction. Unlike chemical treatments, UV sterilization does not affect the water’s composition, taste, or odor, ensuring a natural and stable environment for fish.

Optimal placement of UV sterilizers in RAS

For maximum efficiency, UV systems should be installed after filtration, ensuring cleaner water reaches the sterilization chamber. The key reasons for this placement include:

- Improved UV penetration – Pre-filtration removes large particles that could block UV rays, allowing for more effective disinfection.

- Extended equipment lifespan – Reducing mechanical impurities in the water lowers stress on UV lamps and quartz sleeves, decreasing wear and maintenance frequency.

- Quartz sleeve maintenance – Clean quartz sleeves ensure high UV transmission, maintaining the bactericidal efficiency of the system.

Selecting the right UV sterilizer for RAS

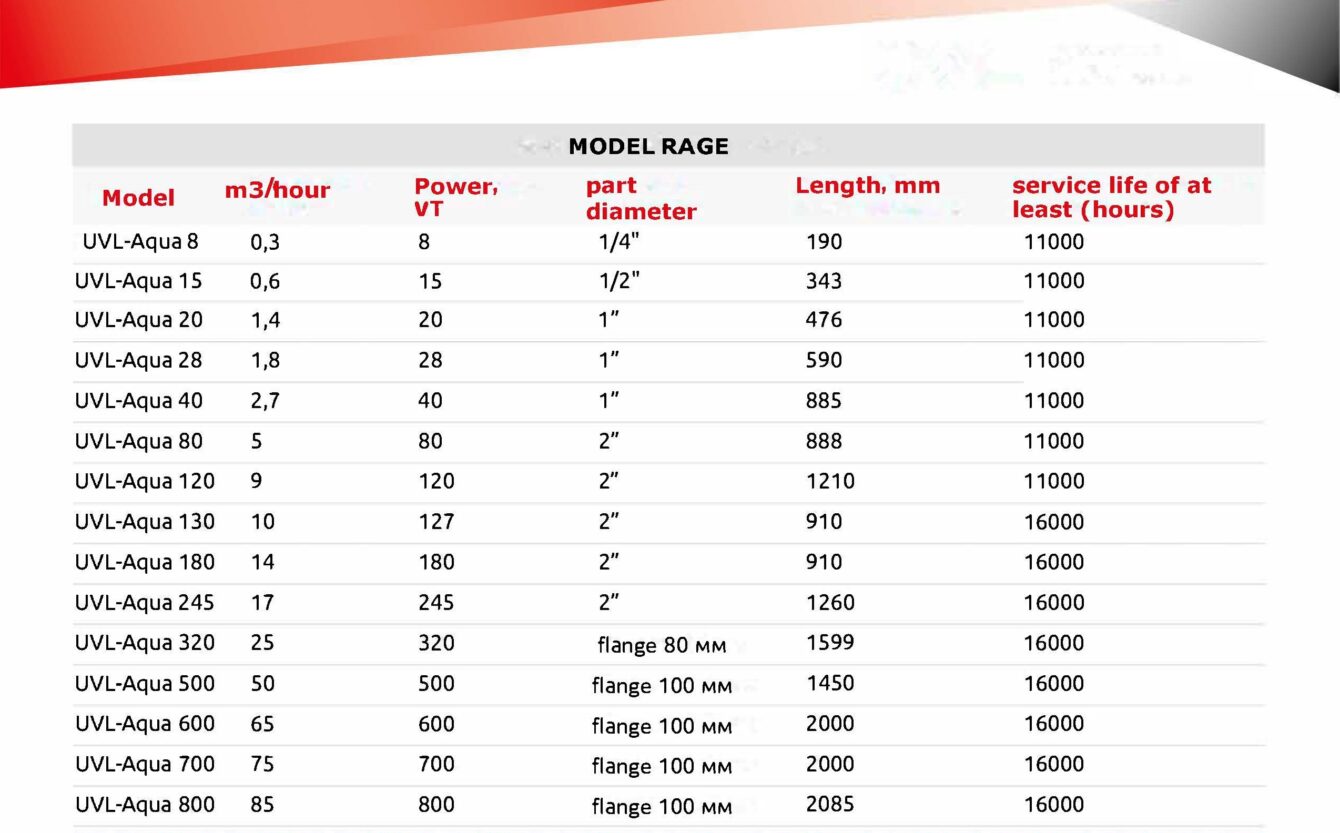

For large-scale fish farms, flow-through UV sterilizers such as the UVL-Aqua series are widely used. When choosing a UV system, it is essential to consider:

- Pump power – Ensures proper water flow through the UV sterilizer.

- Water volume – Determines the required UV dose for effective sterilization.

Consulting with technical specialists can help in selecting the most suitable UV system based on farm size and water treatment needs.

Key benefits of UV disinfection in aquaculture

Implementing UV water treatment in fish farming provides several advantages:

- Reduces disease outbreaks, improving fish survival rates.

- Eliminates the need for chemical water treatment, lowering operational costs.

- Minimizes environmental impact, ensuring sustainable aquaculture.

- Enhances water clarity and quality, promoting healthier fish growth.

Combining UV with other water treatment methods

Many aquaculture facilities integrate ozonation alongside UV disinfection. Ozone rapidly breaks down organic contaminants and odors, improving overall water quality. However, excess ozone can be hazardous to fish and farm personnel.

UV technology serves a dual purpose in such systems by neutralizing remaining ozone, ensuring a safer and more balanced water treatment process. A combination of ozone and UV disinfection offers maximum efficiency in pathogen control and water purification.

Conclusion

UV disinfection has become an indispensable solution for modern aquaculture. By ensuring disease prevention, reducing chemical use, and maintaining high water quality, UV technology supports sustainable and efficient fish farming operations.

For tailored UV solutions for aquaculture, UVL provides a range of advanced sterilization systems. Our specialists are available to assist in selecting the most effective UV equipment for your specific needs. Visit our website for more details.