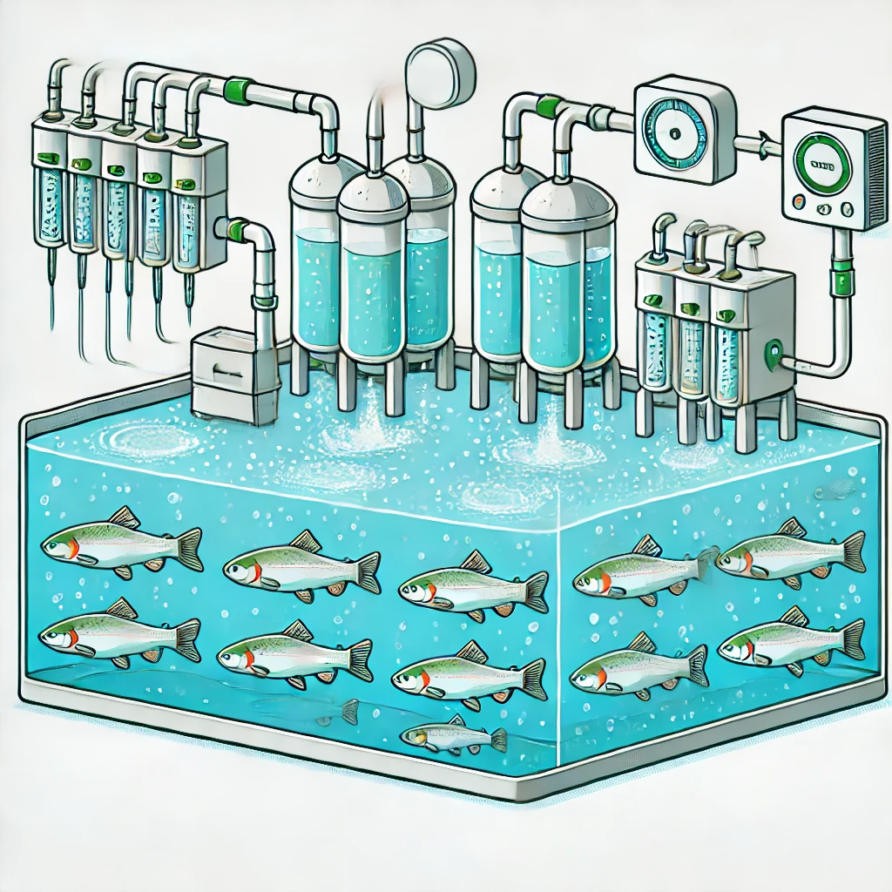

Modern aquaculture technologies have revolutionized fish farming, offering more efficient and sustainable ways to cultivate fish. Recirculating aquaculture systems (RAS) provide complete control over water quality, allowing for optimal conditions for fish growth and reducing dependency on natural water sources. Water treatment is a crucial component of RAS, ensuring clean, stable, and safe water, minimizing contamination, and preventing fish diseases.

Advantages of fish farming in RAS

Fish farms utilizing recirculating water systems are gaining popularity due to their numerous benefits:

- Stable water parameters – Essential for sensitive species like trout and sturgeon.

- Higher stocking densities – Supports increased fish production without compromising health.

- Improved operational efficiency – Less water exchange required, making operations more cost-effective.

Why is water treatment essential?

Unlike traditional fish farming, RAS operates in a controlled environment, meaning that waste, excess feed, and organic matter accumulate quickly. Without proper filtration and disinfection, water quality declines, leading to disease outbreaks and fish mortality.

Statistics on fish mortality in aquaculture:

- 10% loss during the first year

- 5% loss in the second year

- 2% loss in the third year

Effective water treatment in RAS helps reduce these losses, ensuring healthier fish populations and higher productivity.

Key stages of water treatment in RAS

Maintaining optimal water conditions requires a multi-stage filtration process, each step playing a vital role in ensuring clean water:

- Mechanical filtration – Removes solid waste, such as fish excrement and uneaten feed, using drum or disc filters capable of capturing particles as small as 50 microns.

- Biological filtration – Biofilters promote the breakdown of ammonia and nitrites into less harmful nitrates, helping maintain water balance and fish safety.

- Degassing – Removes excess carbon dioxide (CO₂) produced by fish respiration and biofilters, preventing oxygen depletion. Specialized degassing plates improve gas exchange.

- Oxygenation – Ensures adequate oxygen levels for fish survival using aeration systems and oxygen injectors, crucial for species like trout and sturgeon.

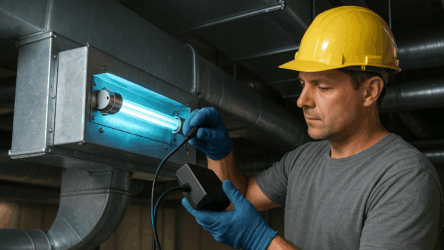

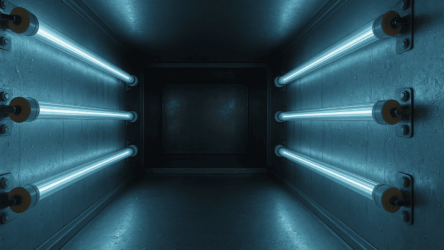

- Ultraviolet disinfection – Destroys up to 99.9% of harmful microorganisms, such as bacteria, viruses, and parasites, without altering water chemistry. UV disinfection does not produce toxic byproducts.

Choosing the right UV system for RAS

Various UV sterilizers are used in aquaculture, depending on the water volume, tank structure, and filtration needs:

- Flow-through UV sterilizers – Designed for large water volumes, selected based on water flow rate (m³/hour).

- Submersible UV modules – Installed in individual tanks, ensuring even UV exposure. Selected based on tank size and geometry.

- Cassette UV systems – Consist of multiple submersible UV modules combined into a high-capacity sterilization unit. The number and power of UV lamps depend on water clarity and disinfection needs.

Conclusion

Water treatment is the backbone of successful RAS operations. A well-maintained filtration and UV disinfection system ensures:

- Optimal water quality for fish growth and health

- Reduced disease outbreaks and lower mortality rates

- Eco-friendly water purification without harmful chemicals

- Higher productivity and cost-efficient aquaculture management

For reliable and effective UV water treatment solutions, UVL offers high-performance UV disinfection systems for recirculating aquaculture farms. Our specialists provide expert consultation, system design, and technical support to help you integrate UV sterilization into your RAS setup.

Visit our official website to explore our range of UV equipment!