UV radiation is a powerful destructive factor, especially for plastic materials. Despite this, some companies continue to use plastic in the manufacture of sterilizer housings and parts that are exposed to direct UV radiation, which significantly reduces their lifespan and increases the risk of failure. This problem can be solved by replacing vulnerable materials with more resistant ones.

Effects of UV radiation on plastic

Plastic structures suffer from UV radiation for a number of reasons:

- Heating. Direct prolonged exposure to ultraviolet rays leads to a significant increase in the temperature of plastic, which causes its deformation and deterioration of strength characteristics.

- Photochemical degradation. UV light causes destructive changes at the molecular level, which leads to loss of color, cracks and brittleness, and further destruction of the material.

To minimize exposure to UV rays, plastic parts should either be covered with protective shields or completely excluded from areas exposed to radiation, replacing them with resistant materials. This approach prolongs equipment uptime and improves performance.

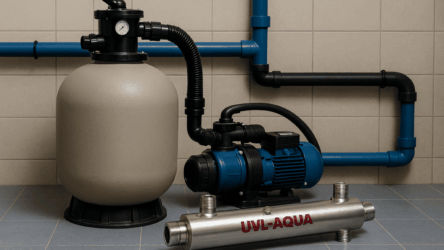

Mistakes when using plastic in UV installations

Some manufacturers make a significant mistake when using plastic in UV sterilizers to disinfect water. Constant exposure to UV radiation causes permanent damage to plastic components: deformation, cracking, disruption of the plastic components, and damage to the water quality.