At the beginning of 2025, a winery approached us with a clear need: to implement ultraviolet air disinfection in a compact, enclosed area where finished wine is bottled and sealed. Their main priority was to improve hygiene at a critical point in the production process—without redesigning or modifying the existing infrastructure.

Site-Specific Constraints

The disinfection system had to be installed inside a small bottling enclosure of roughly 5 m³, which operates in high humidity and undergoes regular washing. Any equipment would need to be both moisture-resistant and compact enough for localized air treatment.

Custom UV Disinfection Solution

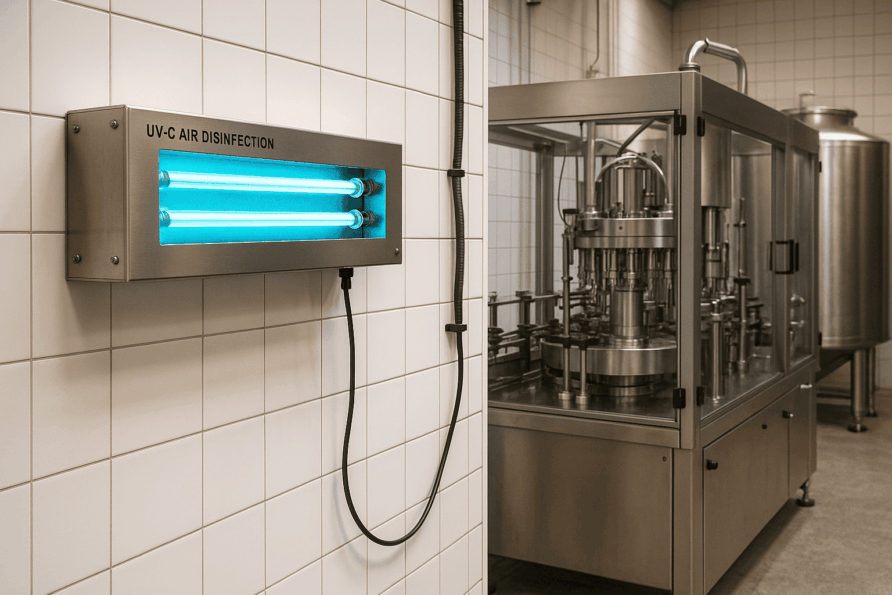

Following a technical consultation, our team recommended the UVL-Aero Prof 55 — a robust UV air disinfection system designed specifically for enclosed, unventilated spaces. Each unit is fitted with a 55-watt bactericidal UV lamp, delivering reliable protection in sensitive zones such as bottling rooms.

Delivered System Included:

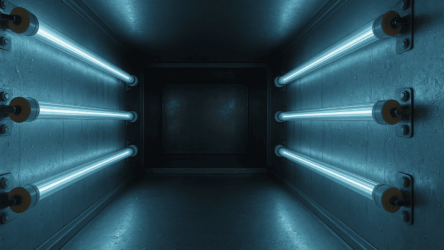

- Two UVL-Aero Prof 55 germicidal air irradiators;

- Two anti-shatter UV-C T8 lamps, safe for food and beverage facilities;

- Corrosion-resistant AISI 304 stainless steel housings with IP65 protection rating;

- Integrated electronic ballasts and extended connection cables;

- Mounting kits and complete technical documentation.

The UV-C lamps operate at a 254 nm wavelength, effectively eliminating up to 99% of airborne pathogens, including spore-forming bacteria. Each lamp is rated for up to 8,000 hours under standard conditions and meets safety and sanitation standards required for beverage production environments.

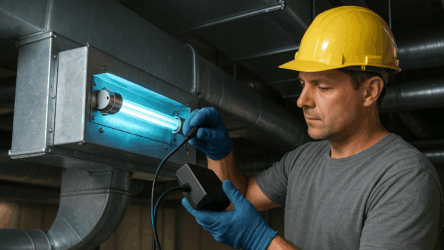

Delivery and Setup Process

Once the project was approved, the equipment was assembled, tested, securely packaged, and shipped via a logistics partner. All operating manuals and documentation were included with the delivery. Upon inspection, the client confirmed that the entire shipment arrived in excellent condition.

Outcome: Improved Hygiene with Minimal Disruption

The winery successfully installed the UV disinfection units, gaining a compact, efficient solution for microbial control at one of the most sensitive stages in their production line. Key benefits included:

- Significant reduction in airborne microbial contamination during bottling;

- Seamless integration without modifying existing infrastructure;

- Reliable performance in humid and wash-down conditions;

- Enhanced hygiene without major capital expenses.

The implementation of UV air sterilizers in the food and beverage sector continues to prove highly effective, especially in confined areas where cleanliness is critical. In this case, careful equipment selection based on site conditions allowed for precise disinfection and improved production safety.