UVL is a trusted manufacturer of ultraviolet disinfection systems for water, air, and surface treatment. We develop advanced germicidal irradiators and high-output amalgam UV lamps, engineered to meet the demanding conditions of modern food and beverage production.

Project Overview

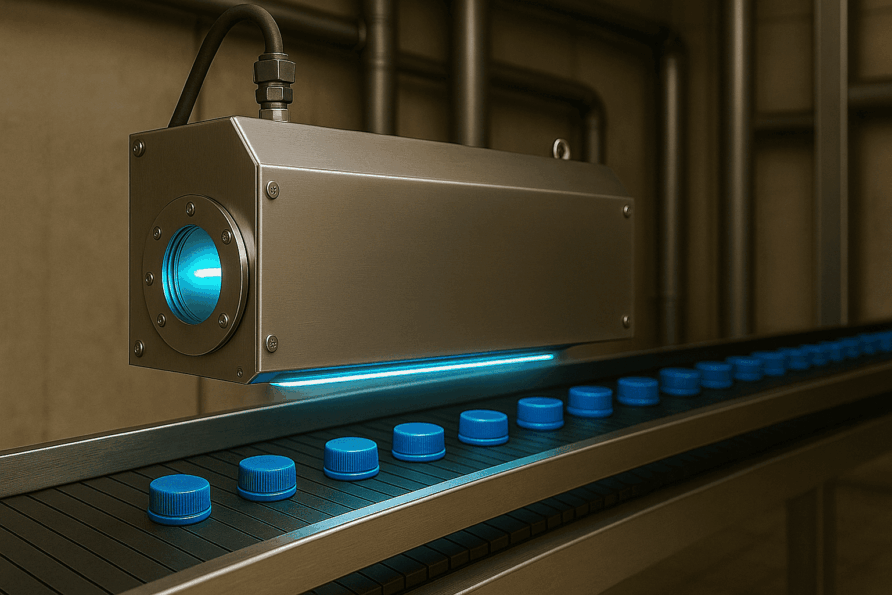

We were approached by a beverage manufacturing facility that produces both non-alcoholic and distilled products. Their objective was to integrate an automatic UV disinfection unit directly into the conveyor line to sterilize PET bottle caps without manual labor, thereby minimizing the risk of microbial contamination.

The production line runs at 26 meters per minute, with a belt width of 100 mm. The integration zone is unstaffed and spatially limited.

Challenges

The client’s main requirements were:

- Fully automated operation with no physical contact with the packaging

- Moisture-resistant and sealed design

- Compact footprint with quick installation

- Compliance with hygiene and safety standards for food production

The goal was to ensure effective UV disinfection during continuous conveyor operation, without chemicals or operator involvement. Additionally, the system had to eliminate any risk of glass or mercury contamination, even in the event of lamp failure.

Our Solution

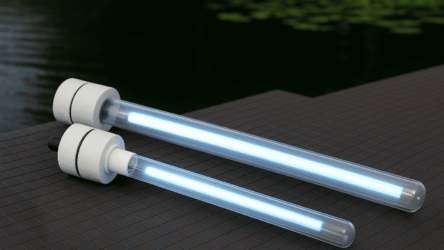

Our engineering team recommended a reliable and off-the-shelf solution: the VOZUV-410 UV irradiator, equipped with a high-intensity amalgam UV lamp (UVL 1980). Key features of the lamp include:

- Anti-shatter design that ensures safety even if the lamp is damaged

- Chemically bound mercury, making it safe for food environments

- Long service life (up to 16,000 hours) and strong temperature resistance

This specific model was already in stock, enabling:

- Immediate delivery with no production delay

- On-site installation by the client’s team

- Cost savings and fast implementation

- No disruption to the production cycle

| Model | Power (W) | Width (mm) | Length (mm) | Availability |

| VOZUF 410x1 | 85 | 120 | 410 | In stock |

| VOZUF 810x1 | 172 | 120 | 810 | In stock |

| VOZUF 1520x1 | 320 | 120 | 1520 | Made to order |

| VOZUF 410x2 | 170 | 270 | 410 | Made to order |

| VOZUF 810x2 | 344 | 270 | 810 | Made to order |

| VOZUF 1520x2 | 640 | 270 | 1520 | Made to order |

| VOZUF 410x3 | 255 | 360 | 410 | Made to order |

| VOZUF 810x3 | 516 | 360 | 810 | Made to order |

| VOZUF 1520x3 | 960 | 360 | 1520 | Made to order |

Technical Highlights

The VOZUV-410 unit is made from AISI 304 stainless steel and is designed for use in moist production environments. It comes fully prepared for quick installation:

- UV irradiator with mounting kit

- UVL 1980 amalgam germicidal lamp

- Electronic ballast (EPRA L-220-1x320-2212-150)

- 4-pin ceramic connector with pre-attached cables

- Protective packaging for safe transport

Installation Guidelines:

- Lamp reaches full power within 1–2 minutes

- Optimal mounting height: 5–20 cm above the conveyor

- Power unit fits standard control cabinets — no rewiring required

Implementation

Once technical specs were finalized, the equipment was picked, packed, and shipped without delay. Despite high warehouse activity, the unit was delivered on schedule. All components were supplied with operating manuals and warranty documentation.

Outcome

The client successfully integrated ultraviolet packaging disinfection into their production line without manual labor. The system reduced microbial risks and improved sanitary control — all while complying with food safety regulations.