Project Overview

A major seafood processor contacted us to improve air sanitation at its facility, where fish is stored, processed, and packaged. The environment presented significant microbial challenges: large volumes of raw product, high humidity, fluctuating temperatures, and constant staff presence. Maintaining clean air in these conditions was critical, especially in rooms operating under a continuous production cycle.

The installation zones covered over 100 m², and the client needed a solution that could disinfect air effectively without pausing production or evacuating workers.

Challenges

The client’s previous disinfection methods had shortcomings. Aerosol treatments required stopping production and clearing personnel, while the existing exhaust ventilation could not ensure sufficient protection against airborne contaminants.

They required equipment that would:

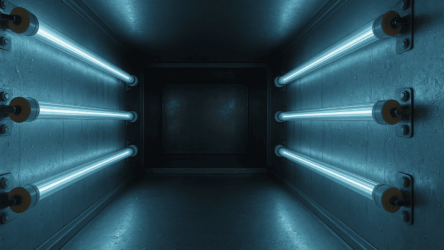

- Provide continuous UV air disinfection while people were present.

- Operate without halting the technological process.

- Meet safety standards for ultraviolet exposure.

- Demand minimal maintenance.

Solution

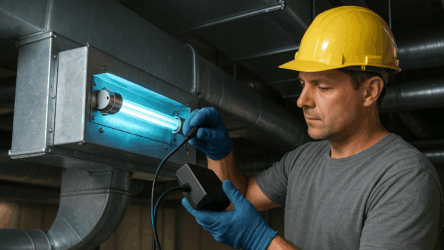

After analyzing the site data and requirements, we proposed six wall-mounted bactericidal air recirculators UVL-Aero 400. Each unit is designed for UV air treatment in spaces up to 200 m³ and delivers a throughput of 400 m³/h.

The UVL-Aero 400 units use amalgam lamps with ozone-free UV lamps, ensuring 99.9 % sterilization efficiency against Staphylococcus aureus. They comply with international ultraviolet safety standards, making them suitable for use around personnel.

Technical Specifications

- Amalgam germicidal lamp (UV lamp lifespan 16 000 h).

- Three axial fans UVLamicon (17.2 W each).

- Durable stainless-steel housing.

- Noise level ≤ 44 dBA.

- Mobile stand with wheels for easy relocation.

- Dimensions: 1200 × 385 × 160 mm.

- Ultraviolet dose: ≥ 385 J/m³.

- Stable operation at 220 V, 50 Hz.

Implementation Details

Our team reviewed all technical documentation to calculate the exact quantity and type of UV air disinfection equipment needed. Production started immediately after prepayment, and shipping was completed on schedule. Packaging dimensions and warehouse schedules were confirmed in advance to ensure seamless delivery.

Using these germicidal UV recirculators at the fish processing plant will:

- Maintain stable sanitary conditions in production areas.

- Reduce the risk of microbial contamination of fish products.

- Lower overall sanitation and disinfection costs.

- Ensure compliance with hygiene standards without unnecessary expenses.

For reliable ultraviolet air sterilizers tailored to your facility, contact us—we will provide a custom solution.